Simon Richenhagen: Transparency is becoming increasingly relevant in logistics. At Krone, we support the transport industry with digital tools in and around the trailer. As an IT service provider, your company advises customers who use a wide variety of transport modes. What role does transparency play for your customers, Mr Röder?

Moritz Röder: It has a very high priority: everyone wants transparency - ideally always along the entire supply chain. People want to know what happens on the road, on the rail, on the water and in the air. But so far, no one has really managed to implement this across the various transport routes. You certainly know this when you have goods coming in and at the same time your customers want to know when they will get their trailer. As a Lufthansa subsidiary, we have traditionally had strong ties to air transport. I believe that we are already quite well positioned there, because a lot of data is very well available. On websites such as Flightradar24, anyone can look up the location of a particular plane. Our sister, Lufthansa Cargo, for example, has its own e-tracking platform on which you can see where your goods are in real time, based on the air waybill. Such approaches are also interesting for other industries outside of aviation. But in my opinion, we should go one step further: We need to make such data available across the different modes of transport on one platform. There are providers who have specialised in this and have been working on it for years. But full transparency throughout the entire transport chain does not yet exist.

Moritz Röder: It has a very high priority: everyone wants transparency - ideally always along the entire supply chain. People want to know what happens on the road, on the rail, on the water and in the air. But so far, no one has really managed to implement this across the various transport routes. You certainly know this when you have goods coming in and at the same time your customers want to know when they will get their trailer. As a Lufthansa subsidiary, we have traditionally had strong ties to air transport. I believe that we are already quite well positioned there, because a lot of data is very well available. On websites such as Flightradar24, anyone can look up the location of a particular plane. Our sister, Lufthansa Cargo, for example, has its own e-tracking platform on which you can see where your goods are in real time, based on the air waybill. Such approaches are also interesting for other industries outside of aviation. But in my opinion, we should go one step further: We need to make such data available across the different modes of transport on one platform. There are providers who have specialised in this and have been working on it for years. But full transparency throughout the entire transport chain does not yet exist.

Richenhagen: We have been offering telematics services for a very long time and can provide ETA data through a cooperation with Shippeo, for example, but I agree with you: we need overarching transparency. I would like to see the industry grow even closer together and perhaps also develop a kind of global language format - to enable the transparency that makes our customers' work easier. I think we should establish a different way of dealing with data: Companies should share it more actively so that customers can benefit from it. At Krone we are already doing that, because we believe that the customer should not have to use different portals from several manufacturers in parallel.

Röder: I think we all know our own data as a company quite well by now. At Lufthansa, for example, it is known at all times where every plane is located. There are similar examples from other industries, especially in logistics. What is important now is that we share this data with each other and do not see it as a pot of gold that we sit on and guard like a treasure. Because data only becomes gold when we are actually able to exchange it with each other and work with it. Especially since I don't always need to know where my consignment is at given time, but only want to be informed if something has changed in its condition or if the ETA has changed - in other words, if I have to take action. This is where the automation of processes comes in: data should no longer have to be processed manually, but should be made available automatically.

“Data only becomes gold when we are actually able to exchange it with each other and work with it.”

Moritz Röder

Richenhagen: Krone has been manufacturing trailers for about five decades. When telematics technology developed, we integrated it into the vehicle. In the case of aircraft, transparency was probably thought of more technologically from the very beginning, wasn't it?

Röder: A lot has happened there in recent years, too. In order to evaluate large amounts of data and make it available, you need technologies such as the cloud, artificial intelligence, Big Data and platforms that are able to store and retrieve the data. These technologies have only recently developed or reached the necessary strength - or have become affordable enough to be brought to the masses. In the aviation context, this means that it is now possible to map a comprehensive digital twin for modern aircraft. This produces terabytes of data that also have to be processed again. In cooperation with us, Lufthansa Technik has developed its own product called AVIATAR. Here, too, it is interesting to see how the data is used. An important application, for example, is predictive maintenance: Using the digital twin, it is possible to reliably predict when the aircraft will need maintenance the next time. For example, mechanics traditionally replace all spark plugs at regular intervals. The digital twin, on the other hand, can show how often each one has fired and accordingly, it can be replaced individually - namely when it really needs to be changed. This saves resources and promotes sustainability.

Richenhagen: Predictive maintenance is also a big issue for us, because nothing is more important than keeping the trailer rolling. The failure of a vehicle can cause great damage, especially if it is loaded with refrigerated goods. We are therefore working on a solution that can anticipate a possible failure and give an appropriate warning. Tyre pressure can also be monitored, for example, Tire Pressure Monitoring protects against damage, breakdowns and accidents. The aim of all this is to enable customers to use our products with as little worry as possible and to this end, we support them in working more efficiently, both economically and ecologically. On the road, this is exactly what digitalisation provides. Is it similar in air transport?

Röder: Definitely. If, for example, I can already coordinate my processes according to when cargo arrives and what condition it is in, I can plan much more efficiently and also react immediately if required.

Richenhagen: What about loading processes, will they also be digitalised and automated for air freight? This is a big topic for us at the moment. We have developed the eTrailer with an electrically driven axle, which can even relieve the tractor and save fuel. At the same time, we are launching a container chassis that automatically adjusts to the right size of container at the push of a button. Are there similar technologies in air freight?

Röder: Well, air freight is very diverse: on the one hand, there are the standardised means of loading, such as air freight containers, which can be loaded relatively automatically. But there is also a lot of individual freight that has to be cleared through customs, and that makes automation difficult again. In addition, a major challenge for cargo airlines is that customers do not always really deliver what they have reported in advance in terms of the dimensions and weight of their goods.

„I think a different way of dealing with data should be established: Companies should share it more actively so that customers can benefit from it.“

Simon Richenhagen

Richenhagen: Just as passengers sometimes wonder whether they might get on board with their slightly larger hand luggage?

Röder: Exactly! We use digital solutions to identify as far in advance as possible where we need to check volumes more closely. So, automation is definitely an important goal in aviation, and at the same time it is not easy to achieve because of the complexity of the business. Another issue that is of course affecting everything at the moment is the bottlenecks that exist in terms of personnel, raw materials or even in the supply chains. Does this present particularly big challenges for you in the manufacturing industry?

Richenhagen: Definitely. As a manufacturer, we are strongly affected by the shocks in the supply chains because raw materials and materials are difficult to obtain and prices have risen enormously. This also affects our customers: More and more freight is being shifted to the road. At the same time, and above all, there is a lack of personnel.

Röder: We ourselves are feeling it too, but our customers even more so. Ports around the world are congested, there are restrictions due to the Corona pandemic, as well as strikes - recently in aviation, but of course also in the ports themselves. All this slows down the flow of goods. At the same time, there is a lot of freight and thus many containers that have to be stored temporarily. For a long time, there was no capacity in the aircraft to transfer such transport: As a rule, passenger planes also take cargo. This so-called ‘belly transport’ fell away for the most part during the pandemic, and the cargo planes were correspondingly burdened.

Richenhagen: In the face of so many challenges what advice do you have for your clients on how to re-establish a certain predictability?

Röder: It is important to realise that you are still capable of acting. In doing so, one should by no means let oneself be guided by a gut feeling, but instead, by facts - and also to develop and strengthen one's own trust in technology. That takes time. At the same time, a high degree of flexibility is required today: even if I have set up a medium- and long-term plan based on data, I have to be able to change it at short notice. The ideal situation is when algorithms make suggestions, perhaps supported by artificial intelligence, and I trust these suggestions because I can be sure that the technology works reliably.

Richenhagen: At Krone we see ourselves not only as a pure vehicle manufacturer, but also as a mobility consultant for our customers. We want to offer them the best solution for their transport task in each case. This is made possible above all by the data that our telematics can reveal, combined with the expertise and experience within the company. In doing so, it is very important that we live and breathe networking and are aware of how important it is to open up to the outside world.

Röder: We also follow this approach. We advise in an open-minded way and have to be wellinformed about everything that is technically possible at the moment and network with startups, among others, in order to know their solutions. You don't have to and can't reinvent everything, but you should collaborate to exploit the greatest possible potential.

Richenhagen: What about sustainability, where does your company stand and what is the situation in the IT sector?

Röder: Sustainability is also a key issue for us at LHIND. That is why social responsibility is also part of our strategy. The United Nations has defined 17 goals for sustainable development, seven of which we are pursuing with particular focus, just like the Lufthansa Group. This is not only about ecological aspects, but also about economic and social aspects, which also include topics such as diversity and education. With regard to our contribution to combating climate change, we support the goal of limiting global warming to 1.5 degrees. For us, this also means continuously recording and reducing our corporate carbon footprint. We are therefore currently examining how we can make our IT in particular, more sustainable through green coding or more efficient architectures, for example, in order to handle data volumes more sparingly and thus conserve precious energy resources. Of course, efficient IT and resource-saving code are just as interesting for our customers. That is why we support them in this area on their way to more sustainability. We can also use modern technologies, such as artificial intelligence, to make routes or processes more efficient.

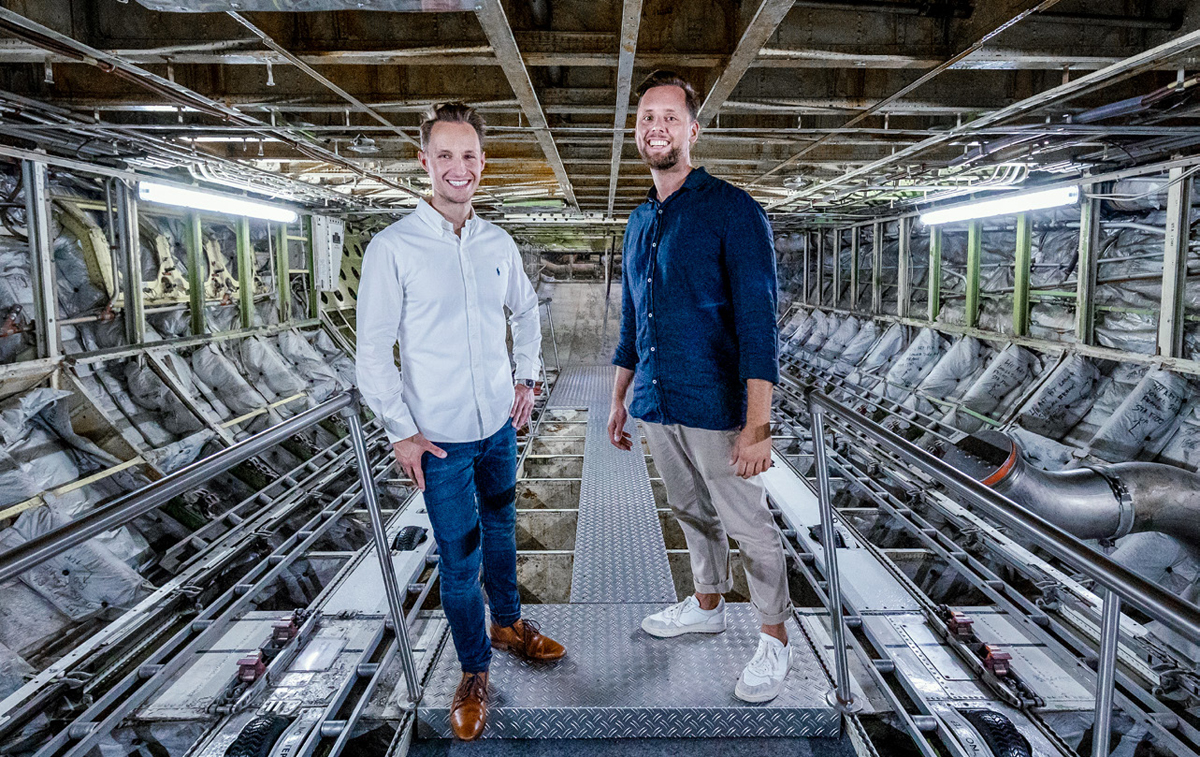

ABOUT THE PERSON

Partnerships also offer us the opportunity to contribute to society. For example, in cooperation with the initiative SPRK, we are taking a global stand against food waste, by offering companies a tool for measuring their sustainability KPIs, together with the Lufthansa CleanTechHub. Also, together with SetLog, enabling easy-to-implement and reliable compliance with the Supply Chain Sourcing Obligations Act, coming in 2023. The last example in particular can have a significant impact on making supply chains more flexible - and the past few years have shown how important this flexibility is in a globalised world. Last but not least, it became clear during this time how much aviation contributes to globalisation and, in particular, to international understanding. Thanks to aviation, we are in a position to personally exchange information across continents from person to person. But being in conversation with other cultures broadens horizons - and that makes a society more valuable.

Richenhagen: This holistic approach is important, no question about it - both within a company itself and on a global level. To do this, you have to be open to new impulses and talk to others. Fortunately, such personal meetings are more possible again.

Röder: Yes, events like the IAA Transportation are immensely important for this. There you can look left and right and break down silos. Personally, I am still concerned that we not only present successes in such discussions, but also can honestly communicate what is perhaps not going well. After all, innovations have often been born from mistakes.

Richenhagen: Absolutely right. Where would you say traffic on the road and traffic in the air can still learn from each other?

Röder: In my opinion, you can no longer separate the two. Intermodality means that we exchange data. And I think both areas can do that even more.

Richenhagen: I see it the same way, the means of transport all interlock and complement each other. Our joint task in logistics is to close gaps to enable a seamless transition and thus also make the entire supply chain more sustainable.

Röder: For all of this, however, even stronger support is needed from politics. It is good and right that, for example, social sustainability is to be strengthened with the Supply Chain Due Diligence Act. But even if it enters into force on 1 January 2023, there are still no precise definitions a few months beforehand of what evidence is required and in what form. As important as data protection is - GDPR needs an urgent revision that also includes the opportunities and potential of new technologies which have a stronger practical relevance.

Richenhagen: We also experience this when we sometimes have to go a long way for new developments via exemptions, for example with aerodynamic components on the trailer, which are not viable due to length restrictions.

Röder: Germany definitely has to become more flexible in this respect in order not to be left behind internationally. At the same time, it has to be said: as a first mover, you usually always come up against obstacles. If you want to be at the forefront and be innovative, you usually run into blockades.

Richenhagen: That's right. It just shouldn't end up that innovative ideas regarding the economy are virtually punished by politics.

Röder: Yes, that can become an innovation killer.

Photos: Gerald Schilling Fotodesign